Why You Should Oversize Your PV Array For Your Inverter

When designing a solar system, it is often smart to size components so that the panels supply 10-20% more wattage than the rating of the inverter. In this article, we’ll explain how oversizing your PV array can maximize your system’s overall efficiency.

Welcome to our solar tech tips series! In this article, we’re going to take a look at a concept that can create a lot of confusion during the system design process: oversizing your PV array for your inverter.

First, the basics: solar panels and inverters both have a wattage rating. For example, a 315W solar panel produces 315 watts, and a 290W micro-inverter can put out a max of 290 watts of power, if it’s available.

When the panel produces more power than the inverter can handle, the excess wattage is “clipped.” Anything above the 290W rating can’t be processed by the inverter, so if the 315W panel is producing at its rated output, 25 watts are wasted by the input limitations of the inverter.

Knowing all this, you might make the reasonable assumption that the panel wattage shouldn’t exceed the inverter wattage, because wasting power is generally a bad idea…right?

But that’s not quite true.

When designing a solar electric system, you’ll get the most bang for your buck if you oversize your panels by 10-20% in relation to your inverter.

It’s counter-intuitive, but it’s true. Here’s why.

Why You Should Oversize Your PV Array

Note: this advice applies to grid-tie systems only. Off-grid systems have different sizing considerations – the inverter is sized to match your maximum load to run your appliances, rather than an average daily usage. Therefore, sizing considerations are different and this advice should not be applied to off-grid systems.

For help going off the grid, check out our off-grid system sizing guide.

In real-world conditions, the panel rarely produces at its rated output. There are two main reasons for that:

- Efficiency Loss: real world factors like temperatures, shading and pollution affect the amount of light hitting your panel. This can cause the panel to produce below its rating.

- Production Curve: The array doesn’t produce a consistent amount of power throughout the day. Production is a curve, with less output during the morning and evening, and peak production at “solar noon.” During off-peak periods, the panel doesn’t produce as much as its wattage rating.

Let’s look at each of these points in more detail.

Standard Test Conditions vs. Real-World Conditions

When manufacturers test panels to give them a rating, they do so in ideal conditions:

- Indoors, at a controlled temperature (about 77°F)

- With a given amount of solar irradiance (1000 watts per square meter)

- At an ideal 90° angle of incidence (light shining directly on the panel)

These standard test conditions measure what the panel is capable in a perfect environment, but the real world rarely delivers these ideal conditions.

In reality, there are a number of factors that can reduce panel efficiency:

- Hot temperatures

- Tilt angle of the array

- Time of day / sun’s position in the sky

- Cloud cover and pollution

Under real-world conditions, a 315W panel rarely produces 315 watts of instantaneous power.

Our general rule of thumb is to ballpark 10% efficiency loss to account for real-world operating conditions. The true number changes based on your local environment, but 10% gives us a good baseline estimate.

Sun Hours & Peak Sunlight Window

For a solar panel to reach peak output, the sun has to be angled so it is directly perpendicular to the array, allowing it to absorb the maximum amount of light possible.

That only happens during a narrow window in the middle of the day. As the sun moves across the sky, the angle changes so that less light strikes the panels. This causes the panels to produce less power.

We use the term sun hours to describe this concept. “Sun hours” refers to the amount of time the sun is in the right position in the sky so that the array can generate power. Sun hours are measured based on an irradiance of 1,000 watts per square meter—the same rating used to test panels under standard test conditions.

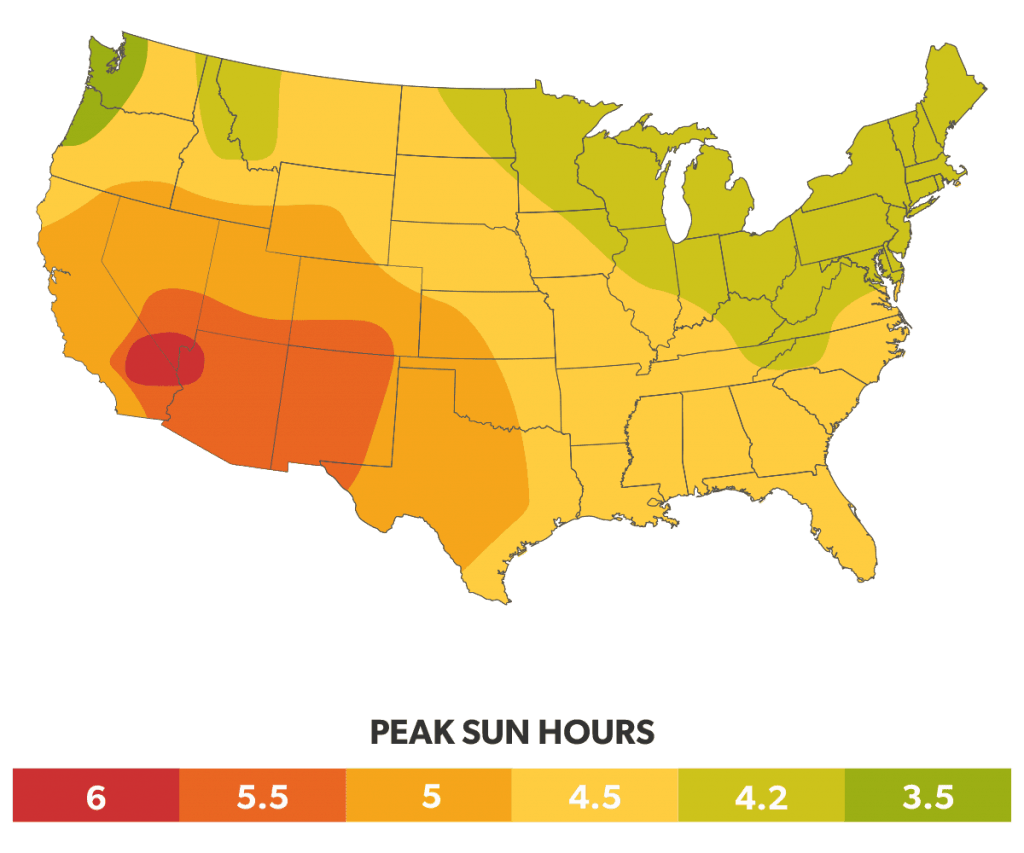

Most places in the US get between 4-6 sun hours per day on average, and all of the meaningful production from the panels comes within this short window. The production graph is a curve where production ramps up as the sun comes out, hits a peak when it is straight overhead, then falls off again into the evening.

The horizontal line represents the input limit of the inverter. Any production above the line (the light orange area) is clipped, or wasted.

The blue area below the line represents untapped potential production. In these periods, the inverter is capable of more throughput, but the panel is not supplying enough wattage to make full use of the inverter’s potential.

Our goal with system design is to balance out clipped production with “lost” potential production. On the graph, notice how the area of clipped production and lost production are roughly equal.

By oversizing the array, you will make better use of your inverter’s capacity, producing more power overall. You want to find the “sweet spot” where you get the most overall production possible per dollar spent on your system – even if that means clipping a bit more power.

There’s another benefit to oversizing that takes advantage of this principle. Most electrical service panels can handle up to 7.6 kW input from solar. Anything larger makes the install more complicated, as you have to either derate the main breaker, or tap into the utility line side.

If you don’t want to tackle a complex install, it might be smarter to oversize your array on a 7.6kW inverter to extend the production window, so that you generate more power in the mornings and evenings, squeezing out that extra bit of production to bring you up to 100% energy offset for your property.

Guidelines for Oversizing Inverters

When designing your system, a good rule of thumb is that your solar panels should be 10-20% larger than your inverter. In hot climates, that can be extended up to 30%, due to greater efficiency losses from heat.

Two real-world examples:

For micro-inverters, we usually pair the 290W Enphase IQ7+ with a solar panel in the 320W-350W range.

For string inverters, the SolarEdge HDWave 7.6kW inverter can be paired with a 8360W-9120W solar array. For example, you could use 3 strings of 335W panels, with 9 panels in each string, for a total of 9,045 watts on a 7,600-watt inverter.

Note that the manufacturers recommend a much broader range in both cases—Enphase suggests 235W-440W panels for the IQ7+, and SolarEdge specs a max of 11,800 watts on their 7.6kW HD-Wave. These guidelines spec what the inverters can safely handle, but we recommend the narrower ranges above to help people maximize their production per dollar spent on their system. Keep in mind that this will vary depending on your climate and other factors that affect production.

Need help with the design process? Request a free consultation with our team. We’ve designed more than 10,000 systems since we came online in 2002, and we can help you navigate challenges like array oversizing to design the best possible system for your needs.